This topic will give you an overview of stuck pipe and how people classify stuck pipe.

Definition of Stuck Pipe

Stuck pipe is a situation when the drill string cannot be moved from the well. The drill string may be partially moved and circulation & rotation may or may not be possible. Personnel on the rig must be able to identify the cause of stuck pipe in order to figure out the right way to free the pipe.

Stuck pipe categories

There are 3 categories of stuck pipes as follows:

Pack off and Bridging

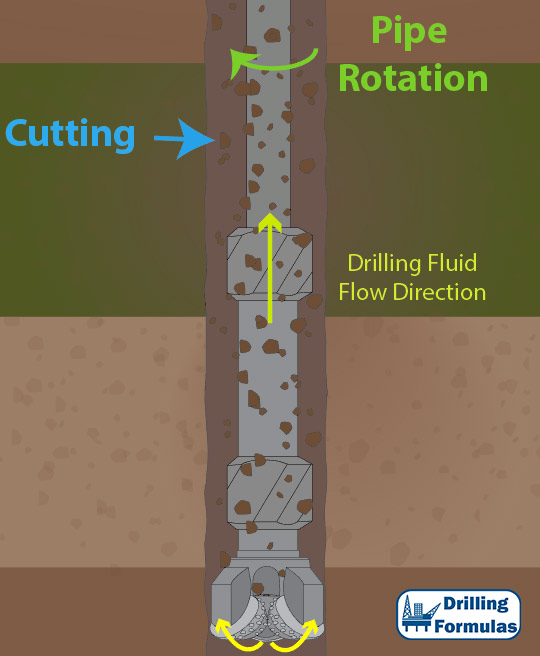

Pack off and bridging are occurred when there is something in the wellbore, such as formation cutting, junk, etc. accumulating around the drilling string/BHA and that stuff blocks the annulus between the drill string and the wellbore. You should remember that either big or small debris can stick in the pipe.

According to statistics around the world, pack off and bridging is the most frequent cause of stuck pipe situations in the world. It normally occurs when the mud pumps are off for an extended period of time, such as when pulling out of a hole. It is quite a tough job to free the pipe in case of packoff or bridging and the chance of success is lower than differential or wellbore geometry sticking mechanism.

Differential Sticking

Differential sticking happens when drill string is pushed against permeable formations by differential pressure between hydrostatic and formation pressure. The frictional force between drill string and formation is so high that you will not be able to move the pipe. The differential sticking tends to easily happen when drilling through a depleted reservoir is conducted. Moreover, this stuck mechanism almost always happens when the drill string has stopped moving for a long time.

Wellbore Geometry

Wellbore geometry stuck pipe mechanism occurs when the shape of the well and the bottom hole assembly (BHA) don’t match each other. Therefore, the drill string is not able to pass through that section.

Note: All of the details about stuck pipe mechanism will be described in later chapters.

References

John Mitchell Drilbert Engineering, 2002. Trouble-Free Drilling Volume 1: Stuck Pipe Prevention. Edition. Drilbert Engineering Inc.

Fanarco.net. 1999. Stuck Pipe Prevention Self-Learning Course. [ONLINE] Available at: http://www.fanarco.net/books/drilling/stuck-pipe.pdf. [Accessed 21 June 2016].