You have learned from 2 previous topics, gas behavior in shut in well and gas behavior with constant surface pressure. Both ways are not how you control bottom hole pressure. In this article, we will use the same scenario but we will control bottom hole pressure constant.

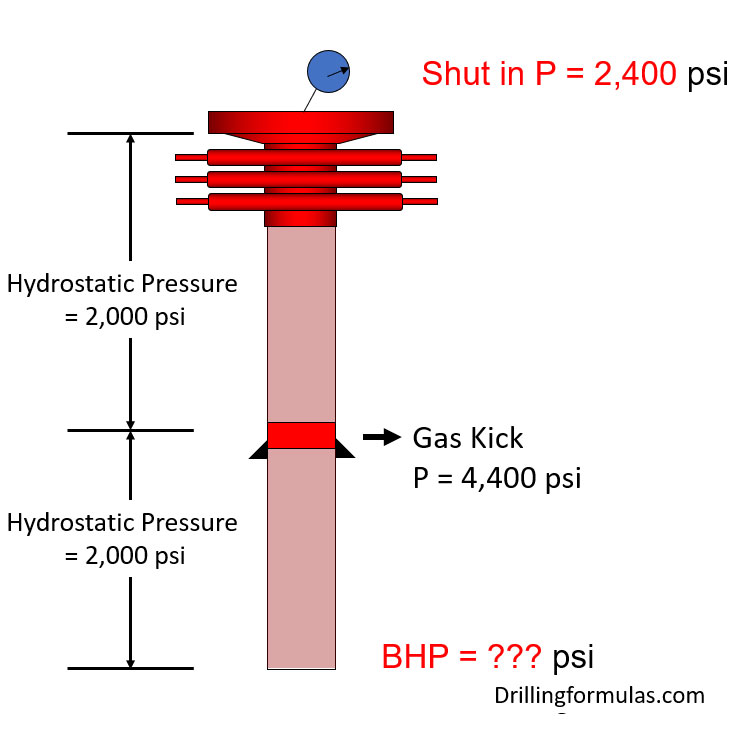

You have the same well. The well is shut-in without pipe in hole. 5 bbl of gas kick is taken and initial shut in casing pressure is equal to 400 psi. Hydrostatic pressure on top of gas is 4000 psi. See the diagram in Figure 1.

Assumptions:

- Volume not change

- No temperature change

- Formation not broken

- No must loss

- 5 bbl of mud expansion = 100 psi (equivalent to hydrostatic pressure)

Figure 1 – Well Shut In Diagram

Determine Gas Kick Pressure

Gas kick pressure at the bottom is equal to hydrostatic pressure above gas kick plus shut in pressure

Gas kick pressure = 4,000 + 400

Gas kick pressure = 4,400 psi

At the bottom, gas kick pressure = bottom hole pressure

Figure 2 – Gas Pressure at The Bottom

For this time, bottom hole pressure will be controlled by the following steps;

- Allow gas to migrate and let pressure increase by hydrostatic pressure of mud that planned to bleed off

- One pressure increases to the required level, bleed off fluid to planed volume by holding surface pressure constant.

For learning purpose, we assume that 5 bbl of mud equates to 100 psi of hydrostatic pressure. The gas is allowed to migrate and the surface pressure is rose by 100 psi. So surface pressure will gradually increase to 500 psi (see Figure 3). At this point, gas kick is still 5 bbl.

Figure 3 – Allow Surface Pressure to Increase

Once 500 psi surface pressure is reached, mud is bled off while maintaining constant surface pressure of 500 pi until bled back volume reaches 5 bbl (See Figure 4).

Figure 4 – Bleed mud volume by maintaining constant surface pressure

What is the bottom hole pressure after bleeding off mud?

Let’s apply the hydrostatic pressure concept.

Bottom Hole Pressure = Hydrostatic Pressure + Surface Pressure

Surface pressure increases by 100 psi.

Hydrostatic pressure decreases by 100 psi due to bleeding off.

Therefore, the bottom hole pressure will be constant since the increase in surface pressure is compensated by the reduction of hydrostatic pressure (Figure 5).

Figure 5 – Maintain bottom hole pressure constant

For this example, the bottom hole pressure is still at 4,400 psi (Figure 6)

Figure 6 – Bottom Hole Pressure still be maintained at 4,400 psi.

With this method, the well is under control without breaking formation or allowing more influx to come. We use this concept in several well control methods.

Conclusion:

- Well control with bottom hole pressure control is the correct method of well control.

- Surface pressure must rise to account for the loss of hydrostatic pressure due to bleeding off mud.

- This concept is used in several well control methods such as driller’s method, wait and weight, volume metric, and lubricate&bleed.

References

Cormack, D. (2007). An introduction to well control calculations for drilling operations. 1st ed. Texas: Springer.

Crumpton, H. (2010). Well Control for Completions and Interventions. 1st ed. Texas: Gulf Publishing.

Grace, R. (2003). Blowout and well control handbook [recurso electrónico]. 1st ed. Paises Bajos: Gulf Professional Pub.

Grace, R. and Cudd, B. (1994). Advanced blowout & well control. 1st ed. Houston: Gulf Publishing Company.

Watson, D., Brittenham, T. and Moore, P. (2003). Advanced well control. 1st ed. Richardson, Tex.: Society of Petroleum Engineers.