Stuck pipe is one of serious situations that sometimes happen on the rig. People put a lot of effort to free stuck pipe; however, when they reach the point that they can not free the pipe anymore, they may need to know where the stuck point is in order to plan to cut or back off drill pipe. This post will demonstrate you how to determine free point constant and calculate where a stuck point is.

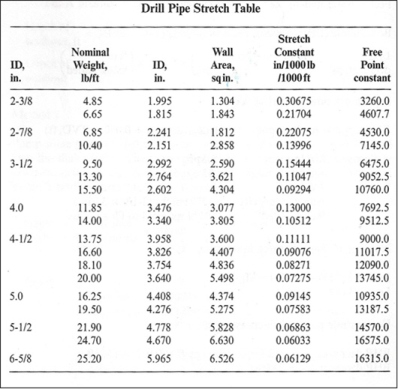

Firstly, we need to know the free point constant which can be found by this following table.

Secondly, determine the depth where drill string gets stuck by the following formula.

Depth of stuck pipe in feet = (Pipe stretch in inch x free point constant (FPC)) ÷ Pull force in thousands of pounds

Example: Determine where the stuck pipe depth is by given information: 3-1/2 in. 9.5 ppf drill pipe, 25 inch of stretch with 30,000 lb of pull force

From drill pipe stretch table, the free point constant is 6475 for 3-1/2 in. drill pipe 9.5 ppf.

Feet of free pipe = (25 x 6475) ÷30

Feet of free pipe = 5396 ft

This mean there are 5396 ft of free drill pipe so when you know this figure, you can plan your wireline work for backing off drill pipe, colliding drill pipe, etc.

Please find the Excel sheet to calculate free pipe.

Ref books:

Lapeyrouse, N.J., 2002. Formulas and calculations for drilling, production and workover, Boston: Gulf Professional publishing.

Bourgoyne, A.J.T., Chenevert , M.E. & Millheim, K.K., 1986. SPE Textbook Series, Volume 2: Applied Drilling Engineering, Society of Petroleum Engineers.

Mitchell, R.F., Miska, S. & Aadny, B.S., 2011. Fundamentals of drilling engineering, Richardson, TX: Society of Petroleum Engineers.

Formulas and Calculations for Drilling, Production and Workover, Second Edition

Formulas and Calculations for Drilling, Production and Workover, Second Edition