Hydro-pressured shale is a common problem in some areas where shale become unstable under period of time. With mud weight in the wellbore higher than formation pressure, the pore pressure of shale is always charged by hydrostatic pressure from drilling mud.

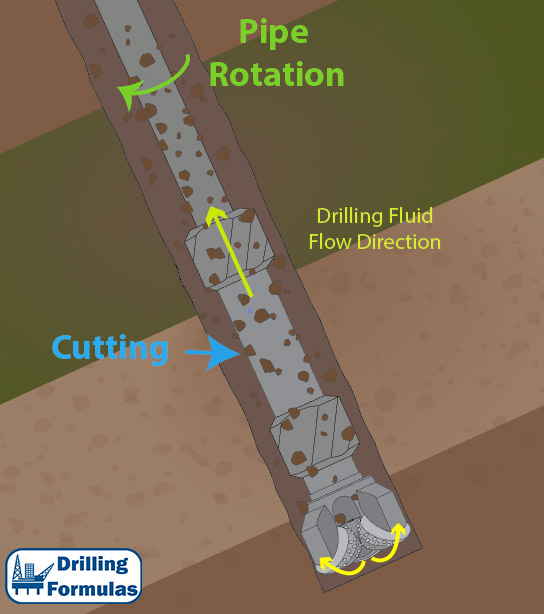

Shale is charged by hydrostatic pressure.

When the well has been drilled for a period of time, shale formations become unstable due to charged pressure and finally shale breaks apart and falls down into the hole.

Shale becomes unstable.

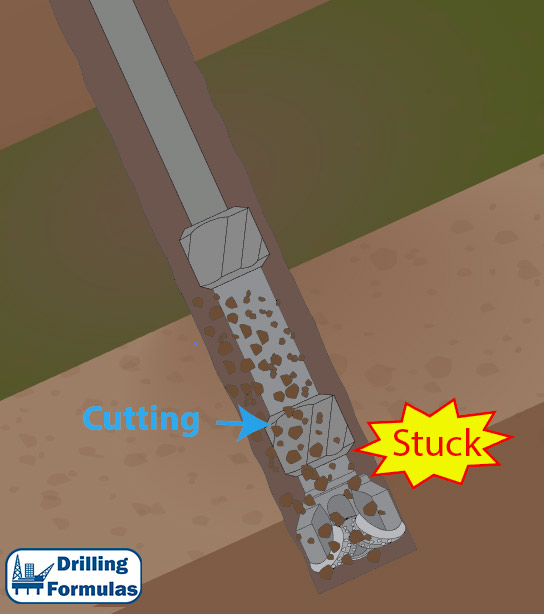

Then, a drill string gets stuck due to hydro-pressured shale which has accumulated in the annulus.

Pipe becomes stuck by unstable shale.

This process is time dependent just like shale instability. It may take days before the stuck pipe situation will occur.

Warning signs of hydro-pressured shale:

• Torque and drag increase.

• Over pull may be observed.

• Observe shale caving in on shale shakers

Indications when you stuck due to hydro-pressured shale:

• When it happens, the hole will be either partially bridged off or packed off; therefore, circulate is restricted or impossible in some cases.

• It could happen while tripping and drilling.

What should you do for this situation?

1. Attempt to circulate with low pressure (300-400 psi). Do not use high pump pressure because the annulus will be packed harder and you will not be able to free the pipe anymore.

2. If you are drilling or POOH, apply the maximum allowable torque and jar down with the maximum trip load.

3. If you are tripping in a hole, jar up with the maximum trip load without applying any torque.

4. Attempt until the pipe is freed and circulate to clean the wellbore.

Preventive actions:

1. Use oil based mud instead of water based mud because oil will not react with shale.

2. Minimize surge pressure and equivalent circulating density (ECD) in the wellbore.

3. Keep mud properties in good shape. Avoid drilling and circulating with thick mud because it creates additional surge pressure.

References

John Mitchell Drilbert Engineering, 2002. Trouble-Free Drilling Volume 1: Stuck Pipe Prevention. Edition. Drilbert Engineering Inc.

Fanarco.net. 1999. Stuck Pipe Prevention Self-Learning Course. [ONLINE] Available at: http://www.fanarco.net/books/drilling/stuck-pipe.pdf. [Accessed 21 June 2016

Steve Devereux, 2012. Drilling Technology in Nontechnical Language, 2d Ed.. 2 Edition. PennWell Corp.