In many situations, a completion string may consist of several size of strings and components so total axial force must be carefully considered by applying a free body diagram concept. When the tubing string is free to move, forces will affect the tubing above where the force is applied.

Tapered String

Tapered string is a string which consists of more than one size of tubing. Hence, forces acting at tapers must be accounted for. Force depends on configurations of pipe and pressure and it will either decrease or increase surface load.

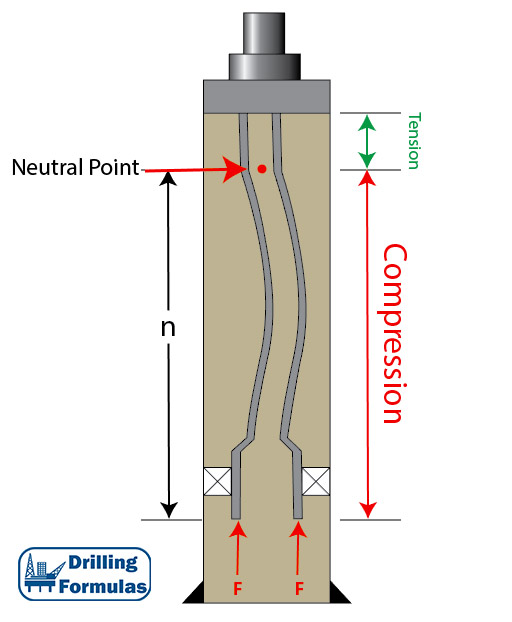

Figure 1 illustrates diagram of a tapered completion string. Wherever in the string there is a difference in outside diameter or inside diameter, there will be downwards or upwards force acting against the tapered edge. It is imperative to analyze each ledge and combine all the results in order to see the total effect. From Figure 1, F1 and F2 cause compression, but F3 creates tension force.

Figure 1 – Tapered String Configuration

Continue reading →