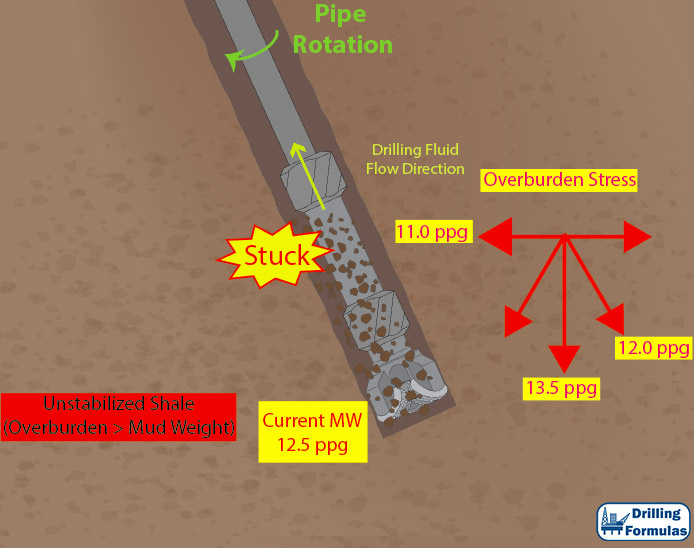

While drilling into naturally fractured formations, pieces of formations fall down in the annulus and can cause a stuck drill string.

Stuck pipe by naturally fractured formation

Warning signs when you get stuck due to Naturally Fractured Formation

• Drill into potential naturally fractured zones as limestone, sand stone, carbonate, etc.

• Observe big caving formations on shale shakers while drilling

• Observe volume to fill the hole is more than a normal hole size

Stuck identification for Naturally Fractured Formation

• This situation can occur during drilling or tripping.

• Torque and drag are suddenly changed and erratic while drilling.

• Over pull off slip is noticed.

• Circulation could be restricted (you may get or not get good circulation)

What should you do for this situation?

1. Stuck while moving up, jar down with the maximum allowable trip load without applying any torque!!!

2. Stuck while moving down, jar up without apply torque

3. Pump weighted hi-vis sweep with the maximum allowable flow rate

Preventive actions:

1. Keep mud in good shape. Good and thin mud cake can support fracture formation in some cases.

2. If the suspected zones are drilled, you should take the time to circulate the hole clean before making headway.

3. Start and stop circulation slowly to minimize surge pressure.

4. Work pipe with restricted speed to prevent surging formations.

5. Tripping speed should be slow while BHA is being run into suspected zones.

6. The fractured formations require time to get stabilized.

References

John Mitchell Drilbert Engineering, 2002. Trouble-Free Drilling Volume 1: Stuck Pipe Prevention. Edition. Drilbert Engineering Inc.

Fanarco.net. 1999. Stuck Pipe Prevention Self-Learning Course. [ONLINE] Available at: http://www.fanarco.net/books/drilling/stuck-pipe.pdf. [Accessed 21 June 2016

Steve Devereux, 2012. Drilling Technology in Nontechnical Language, 2d Ed.. 2 Edition. PennWell Corp.